Insulate Steam Distribution and Condensate Return Lines

Uninsulated steam distribution and condensate return lines are a constant source of wasted energy. Insulation can typically reduce energy losses by 90% and help ensure proper steam pressure at plant equipment. Any surface over 120°F should be insulated, including boiler surfaces, steam and condensate return piping, and fittings.

Insulation frequently becomes damaged or is removed and never replaced during steam system repair. Damaged or wet insulation should be repaired or immediately replaced to avoid compromising the insulating value. Eliminate sources of moisture prior to insulation replacement. Causes of wet insulation include leaking valves, external pipe leaks, tube leaks, or leaks from adjacent equipment.

Example: In a plant where the value of steam is $4.50/MMBtu, a survey of the steam system identified 1,120 feet of bare 1-inch diameter steam line, and 175 feet of bare 2-inch line both operating at 150 psig. An additional 250 feet of bare 4-inch diameter line operating at 15 psig was found. From the table, the quantity of heat lost per year is:

1-inch line: 1,120 feet x 285 MMBtu/yr per 100 ft = 3,192 MMBtu/yr

2-inch line: 175 feet x 480 MMBtu/yr per 100 ft = 840 MMBtu/yr

4-inch line: 250 feet x 415 MMBtu/yr per 100 ft = 1,037 MMBtu/yr

Total Heat Loss = 5,069 MMBtu/yr

Given a boiler efficiency of 80%, the annual cost savings from installing 90% efficient insulation is:

0.90 x $4.50/MMBtu x 5,069 MMBtu/yr = $20,530

What type of insulation is good

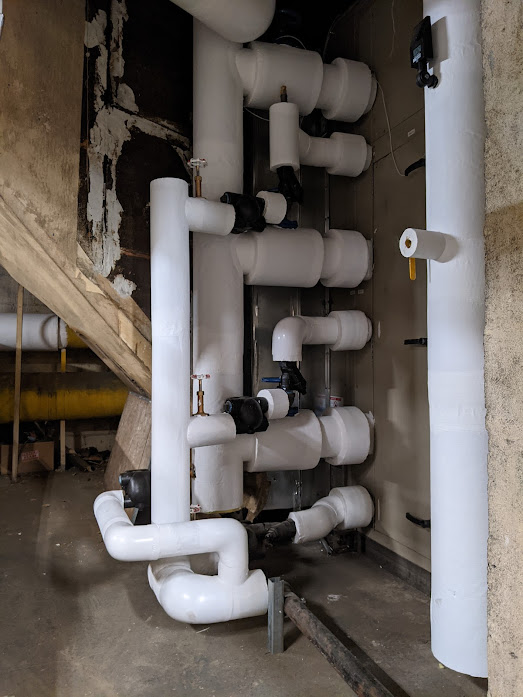

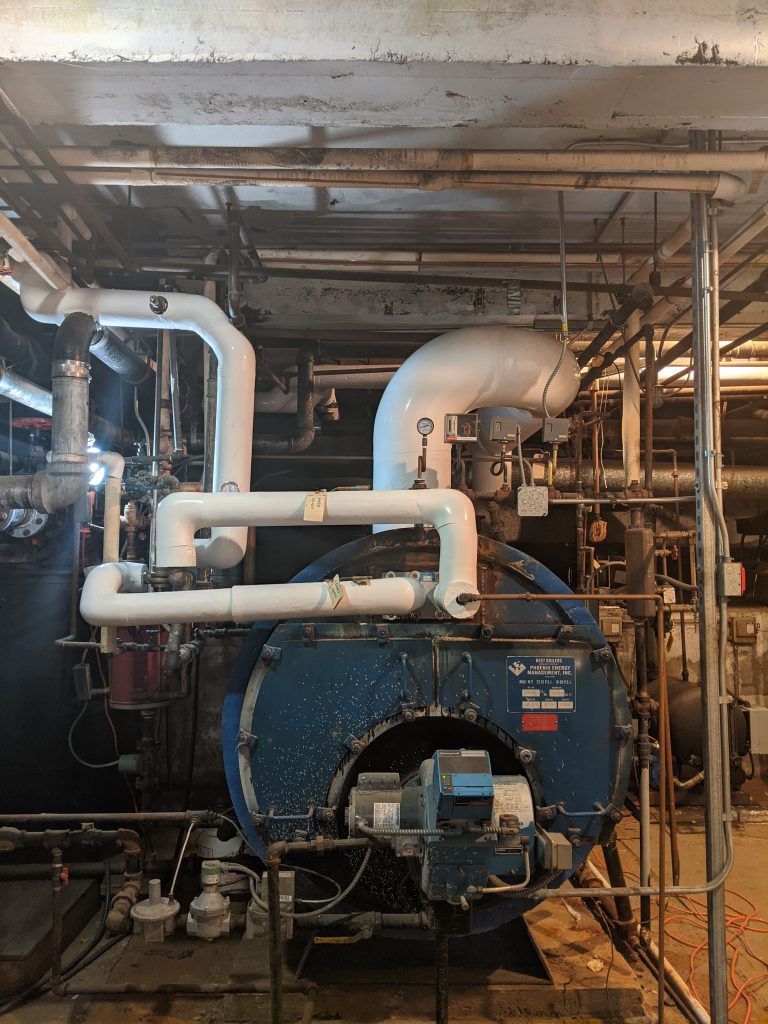

Fiberglass insulation is made especially for pipe and boiler applications and can be used on boiler piping insulation with temperature ranges from -20 degrees Fahrenheit up to +500 degrees Fahrenheit which covers the range of temperatures if you have either a steam boiler or a hot water boiler. Fiberglass insulation (as in the photos) will make the best type of insulation for either steam or hot water boiler piping.

We provide fiberglass pipe insulation with a jacket on the outside and an adhesive strip to join it after we wrap the pipe.

That makes it look professional and neat, and it is also durable.